Today’s mobile or ‘kinematic’ scanners are well-developed, reliable tools that consistently deliver accurate results across multiple applications. Despite this progress, some industries remain cautious, relying on more traditional methods. As handheld mobile scanners become more varied, understanding the differences between these options and their specific advantages is key to achieving optimal project outcomes and maximizing return on investment.

Before looking at handheld scanners in particular, it is important to understand where mobile scanning came from, and which applications suit it best. Laser scanning used to rely exclusively on static, tripod-based scanners that – while essential for many situations that require high accuracy – required more set-up time and could only be operated by experts with years of experience under their belts. Since then, however, technological advancements have led to the introduction of compact and portable mobile scanning devices for reliable 3D data capture in a wider range of use cases. These cater to a user base that appreciates accuracy, but also prizes ease of use, flexibility and speed.

Mobile scanning technology has quickly evolved, and various mobile scanning solutions exist, including vehicle- and robot-mounted systems as well as handheld systems, all offering fast, efficient and comprehensive 3D data capture while moving through an environment. This makes them suitable for projects in a range of industries and applications where speed and ease of use are essential.

Versatile solution

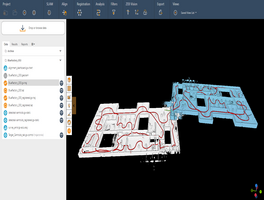

Handheld scanners set themselves apart by enabling rapid and effective data capture of smaller, specific areas, spaces, structures or elements, such as the interiors and facades of individual buildings. It is important to note that capabilities vary widely, with certain scanners better suited for quick dimensional estimations and others designed to collect rich data in high-accuracy applications. The more sophisticated scanners offer a versatile solution to professionals in industries including architecture, engineering and construction (AEC), manufacturing, real estate and public safety.

In the AEC industry, for example, the speed of data capture is critical to keeping projects on schedule and avoiding costly delays. Handheld systems allow professionals to quickly scan construction sites at different stages of a project to ensure materials and installations are fitting as planned. In one project in downtown New York, for example, renovation was planned for a large building, requiring new as-built drawings. A handheld scanner accurately captured the entire five-storey building, comprising 120 rooms and 4,500m2, in just 90 minutes. The result was an accurate 3D point cloud of the entire interior of the building.

Similarly, speed is often a priority in public safety applications. Handheld scanning systems allow law enforcement agencies to capture crime scenes quickly, preserving crucial data without disrupting the scene for long periods. For example, in a high-profile murder investigation in the Amazon, members of the Brazilian Federal Police used handheld scanners in their forensic investigation. Using a handheld scanner enabled the team to quickly capture the scene before any crucial evidence could degrade. They used the captured data to build a forensic digital twin, allowing them to superimpose evidence from different days and meticulously reconstruct the whole crime.

Ask yourself the right question

When choosing between a static and mobile scanner, people often oversimplify it as a trade-off between speed and accuracy. Instead, the real question should be: ‘What is the most efficient way to gather the 3D data I need to generate meaningful insights?’. Even within one project, the answer to that question can differ. If you’re updating the floor plan of an old building, for example, scanning a simple hallway may just require a single scan from one location. Using a mobile scanner would not offer significant efficiency benefits over a static scanner. However, for capturing the building’s staircase, for instance, a handheld mobile scanner could be up to ten times faster, because you can scan as you walk rather than setting up a static scanner several times. Multiple technologies from the same vendor can be seamlessly deployed in the same project nowadays because the various systems use the same software processing workflow. This reduces the additional data processing workload.

One factor when using multiple systems is cost. However, to put the extra cost in perspective, users can think about the return on investment (ROI) thanks to improved efficiency and time savings. If you can now complete two jobs in a day rather than one, the additional investment quickly pays for itself. Efficiencies also come from not having to stop operations in the area you capture, such as on a busy construction site. The more frequently you use these systems, the greater the savings, and the quicker the payback.

Considerations when choosing handheld

When choosing between different handheld scanners, users should consider a variety of factors, including:

- Simplicity of capture and freedom of movement: Every minute of wasted time snowballs over a project, reducing the ROI. Data capture efficiency is maximized with scanners that function well in multiple orientations and allow the user to move constantly without stopping.

- Scanner weight: When scanning for hours every day on the move, even a couple of kilograms can make a difference to the physical burden. Moreover, many countries have laws governing how long workers can carry equipment in a certain weight category.

- Desired output: Some mobile scanners offer more data accuracy, which is important if you need precise measurements for detailed analysis or design adjustments. Others offer a better-looking point cloud, providing better visualization for presentations and reports when communicating with other stakeholders. Some scanners even allow you to view a colourized scan on your smartphone in real time as you walk around, and export that immediately without additional data processing. This could be essential when quick on-site decisions are needed.

- Data processing speed: Fast-paced projects, such as active construction monitoring or scanning hundreds of apartments in order to sell them, require quick turnaround times on the same day. For periodic scans, such as for annual facility documentation or renovation planning, it is usually no problem if the data is processed overnight.

- Processing flexibility: Cloud-based data processing is often preferred for its simplicity and avoids having to pay for servers. However, there are situations in which you may need to process the data using your own hardware – e.g. in high-security industries where data sensitivity is a concern, to achieve quick processing in remote locations without Wi-Fi or a mobile connection, or simply to suit the current workflow. Flexible handheld systems offer both options, allowing you to choose the best workflow for your needs.

- Cost: When evaluating the cost of the purchase, look beyond the initial cost of the technology to also take the lifetime costs and long-term savings into account. For example, selecting a scanning solution that ensures a streamlined workflow and cuts down the scanning time will lead to substantial savings in human resource costs. Similarly, choosing a solution that cuts down on the time it takes to clean up data can significantly reduce the overall operational cost.

Better outcomes

As mobile scanning technology continues to evolve, its ability to deliver fast, accurate and actionable data will only improve. With mobile scanners – whether vehicle-mounted, robot-mounted or handheld systems, depending on their specific needs – industry professionals can streamline their workflows, boost productivity and ultimately drive better outcomes.