SEOUL, South Korea, June 11, 2023 /PRNewswire/ — The 14th DN Solutions International Machine Tool Fair (DIMF) ended in success after showcasing the latest machine tool technology as well as the future direction of machine-tool digitalization.

DN Solutions announced that DIMF 2023, held at BEXCO in Busan and the DN Solutions’ Seongju Plant in Changwon from June 5th to the 8th, wrapped up successfully after hosting 4,500 customers from 55 countries including Korea, U.S., China, India, and Turkey.

DN Solutions has held DIMF every other year since 1997 to introduce newly developed machine tools and new technologies to customers. Over that time, more than 40,000 customers from Korea and abroad have participated in DIMF.

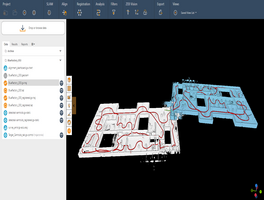

In this year’s exhibition, DN Solutions showcased a total of 65 models, including 40 new models equipped with the DN Solutions’ latest technology such as 5-axis/multi-tasking machining, high-productivity automation, and smart manufacturing solutions. The main exhibition hall at Busan BEXCO was composed of six themes such as automation, digital transformation & CNC, smart factory & AI, ESG, and machining technology. DN Solutions introduced a variety of solutions that attracted attention, including machine tools equipped with its latest machining technology, automation solutions linked with the loading and unloading devices for a variety of applications, machine tools and collaborative robots, and robot solutions that showcase the cell-level automation of autonomous mobile robots.

The implementation of digital twin technology also caught visitors’ attention, which displayed the present condition of the machining factory, and the operation of a COBOT attached to machine tools and AMR. DN Solutions presented its technology direction for the features essential for smart machines, by introducing wireless IIoT technology applied with BLE technology, wireless measuring instrument interface technology, and voice recognition technology. DN Solutions also exhibited a mist-free solution for oil mist purification in the ESG zone. This solution saves energy by minimizing motor power consumption by reducing the size of the purifier from the factory level to the individual machine-tool level.

The Seongju Plant, DIMF’s second exhibition site, was equipped with a production infrastructure that is optimized for large-sized machine tool models for industries such as oil, gas, and aviation. Large-sized machines designed to machine large parts were on display, including the ram-type vertical turning center optimized for the aerospace parts industry, the multi-purpose bridge mill for applications such as mold machining, and a machining center for special applications that use friction stir welding technology.

Kim Wonjong, CEO of DN Solutions, was quoted as saying “At this exhibition, we introduced machine tools and solutions that implemented our cutting-edge machining technology. DIMF allowed us to prove that we have grown from a machine manufacturer to a provider of integrated manufacturing technology solutions. DN Solutions will lead the new digital transformation in manufacturing and become the world’s best manufacturing technology company not only through continuous innovation, but also by showing customers how they can practically apply these innovations to improve their success.”

SOURCE DN Solutions