Lidar News recently had the opportunity to interview Kathie and Rick Tetreault, the founders of Saddleback Surveys, based in Irvine, CA about their investment in Lidar and 3D laser scanning. Here are their valuable insights.

Can you please provide a brief overview of your professional background and experience with 3D laser scanning/lidar technology, as well as a brief history of the growth of your company and its use of 3D technology? Please include an idea of the timelines.

After attending ILMF (International LiDAR Mapping Forum) in 2012 Saddleback Surveys, Inc. (SBS) became hooked on LiDAR, and its many uses. Half of our staff holds a Bachelor of Science in the surveying and mapping fields, so formal education and lifelong learning have played a big part in our LiDAR journey. After much research and many more conferences, Saddleback made the trek to visit LiDARUSA in Alabama. After seeing the equipment perform in real life situations, not just on the conference floor, we decided to commit in 2018. We purchased a custom “A Series-Hiway Mapper” system for Mobile Mapping and Snoopy (INS) with a Velodyne HDL-32 for our UAV / Drone group. These systems have provided us with the opportunity to grow our client base.

Can you provide an inventory of some of the primary 3D surveying and mapping hardware and software that you currently use, as well as any other related products? Please include an idea of the timeline of purchases.

In 2018 SBS started investing in our scanning hardware and software.

We use 2 FARO 330 Focus’ and the Velodyne HDL-32 scanner, in addition to the 360° Ladybug 5 camera.

Our workflow includes the following software platforms:

For initial data reduction and point cloud generation we use Inertial Explorer, Scanlook PC and Scanlook Ladybug from LiDARUSA.

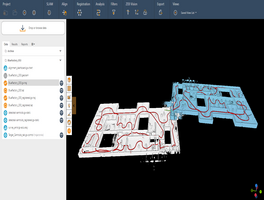

For extraction of the data we use a combination of software platforms, such as Global Mapper, Trimble Business Center (TBC), Cloud Compare and LiDARUSA’s “MyPointClouds.com” for client viewing.

A lot of research went into the hardware and software prior to our purchase. Most of these platforms were purchased right after we received the Mobile Mapper and the UAV.

What attracted you to the use of LiDARUSA products? Did you look at other products? Why did you choose them?

As a smaller, woman-owned, land surveying firm you just cannot beat the value and customer service you get with LiDARUSA. After talking with Jeff and his group, we felt their companies’ innovative culture, and ours would be a good match. After receiving the equipment, we had a few conversations with LiDARUSA. Saddleback Surveys suggested moving the camera position, so that the antenna would not show up in the data. We rebuilt the rack system for the Hiway Mapper. This is now the system layout that is used by LiDARUSA systems. This would not happen with a larger distributor.

We initially looked at Leica terrestrial scanners in 2012 and then again in 2017 when we also looked at the Trimble systems.

How do you integrate LiDARUSA products into your workflows? What were some of the challenges with that? What were some of the best practices and lessons learned?

As soon as the equipment arrived SBS immediately jumped in with both feet. Initially we paralleled our LiDAR systems with conventional surveying and photogrammetry for our own QA/QC. As we became more comfortable with the equipment and processing methods we started experimenting with the workflow.

Some of the lessons learned were based on project control, vehicle speed and spacing and how to “drive” the project with independent segments. Always being aware of these variables allowed us to keep the data clean and the files manageable.

Can you provide a brief overview of two or three of the projects where you made use of LiDARUSA’s technology? Can you provide any thoughts on time savings vs. other methods? Any thoughts on return on investment?

Our clients are the main beneficiaries of Saddleback’s transition into LiDAR. The improved safety and cost savings are the main selling points.

Our Newport Boulevard Project, in Costa Mesa, CA was a busy 6 lane divided highway. The survey scope required cross sections every 25’ with a 10’ grid at all intersections. All work was to be survey grade +/- 0.03 foot. Our control for the project was about every 350’, on both sides of the road, plus one near the centerline of the street. In 5 different passes, we were able to collect survey grade data for 2 miles in less than an hour.

As part of the QA/QC over 1500 survey shots were taken by a third party surveying firm for checks, proving that all data was within tolerance. Over 7000 points were extracted for the project.

Our Falcon Ridge transmission line project, spanned 18 miles within 2 cities, in San Bernardino County, CA. The newly built transmission line owned by a major utility needed to be documented for post construction. In 2 passes and 2 hours we were able to see all wires, conductors, measure all clearances and pinpoint the centerline of each TSP (Tubular Steel Pole) and tower. This effort was also used to prepare a record of survey for the transmission line alignment.

Here is a link to the point cloud: http://mypointclouds.com/projects/e6b62a8e-ac81-4190-80b1-f4e5e50760ef-SADDLEBACK_SURVEYS_FALCON_RIDGE_TRANS

Here is the link to the project video: https://www.dropbox.com/s/scifr4uyedau0j7/Falcon%20Power%20Trans.mp4?dl=0

What do you see in the future for the use of 3D technology on your projects? Are you investigating other advanced technologies that will open up new business opportunities?

The hardest thing to do when working with 3D technologies is getting the surveying and engineering communities to buy into the technology. For some reason everyone loves and trusts drone data from photogrammetric methods, but put a LiDAR unit on that drone, or a vehicle and it becomes a mystery.

My main concern with the future of scanning and 3D technology is the data collection and reduction. For the data to be used for engineering and design purposes, LiDAR needs to be controlled (targets on the ground) with survey grade control, managed and reduced by someone who understands the errors that can surface with the data, preferably a Land Surveyor. When Land Surveyors did not embrace GIS, we lost control of the data and the accuracies of the system.

The construction and utility sectors love LiDAR and seek Saddleback Surveys out, for their projects.

To learn more about Saddleback Surveys CLICK HERE.

To learn more about LIDARUSA CLICK HERE

Note – If you liked this post click here to stay informed of all of the 3D laser scanning, geomatics, UAS, autonomous vehicle, Lidar News and more. If you have an informative 3D video that you would like us to promote, please forward to editor@lidarnews.com and if you would like to join the Younger Geospatial Professional movement click here.