Latest upgrade features a game-changing algorithm that automatically assesses surface damage without the need of human intervention

Lévis, Québec, June 14, 2023—Creaform, a business unit of AMETEK, Inc. and the worldwide leader in portable 3D measurement solutions and engineering services, announced today that it released a new version of VXintegrity TM, its acclaimed solution for surface damage assessments that is accessible to all non-destructive testing (NDT) service companies across multiple sectors.

Industry-first new algorithm

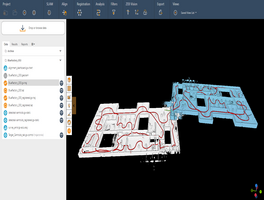

VXintegrity is a powerful NDT software platform, launched by Creaform last year, that integrates all analytical functions and tools into an intuitive, user-friendly interface for inspection teams and service companies. Composed of four software modules, VXintegrity has been designed specifically to solve the challenges of asset owners in a wide range of industries, including aerospace, oil & gas, power generation and mining.

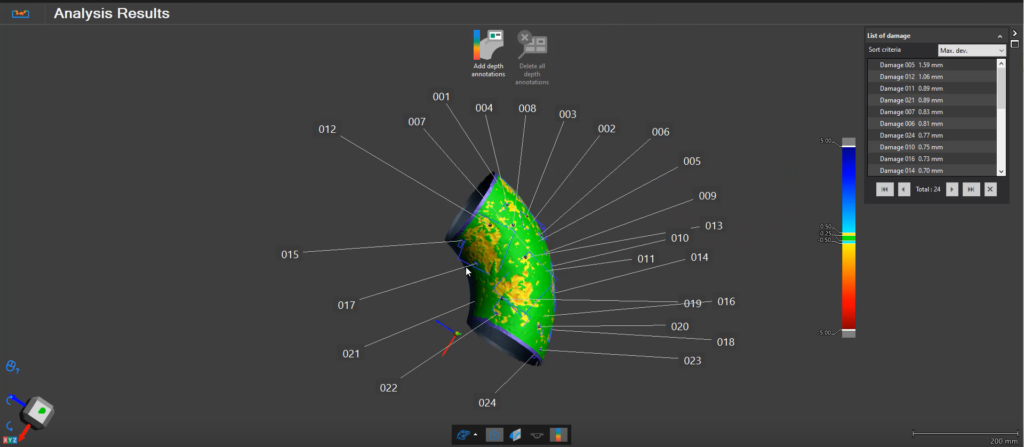

The most significant change is VXintegrity’s game-changing algorithm, which eliminates the need for human interaction to analyze any surface and ensures highly repeatable results. It also removes all the limitations of simpler algorithms, which paves the way to inspection applications on complex components, such as very aggressive double-curvature geometries, elbow pipes, T-joints, valves, advanced nozzles, and boiler tubes. This algorithm is revolutionary for 3D surface assessments as it does not require a CAD model reference or any manual interventions with the data to identify the area of interest.

‘’By developing a dedicated NDT software platform, Creaform is showing the world its commitment to the NDT market and willingness to invest in developing the most innovative 3D scanning solution for surface damage assessment. Version 1.1 is in alignment with this commitment. Our newly reconstructed algorithm beats all other approaches on the market,” said François Lachance, Product Manager at Creaform.

“Since the launch last year, the reception of VXintegrity has been really positive. Many new customers were really impressed by the solution’s performance and agreed that the return on investment of the technologies wouldn’t be too long to achieve,” added Jérome-Alexandre Lavoie, Creaform’s Director of Product Management. “VXintegrity works seamlessly with Creaform’s HandySCAN 3D handheld scanner, which facilitates and accelerates NDT workflows, even in a tight labour market. This is the value Creaform brings to the table: powerful 3D scanners and complete, integrated 3D measurement software.

About Creaform

Never Stop Innovating, a motto that represents the core values of Creaform, from its beginning in 2002 all the way to 2022, which marked the 20th anniversary of the company. To this day, Creaform continues to develop, manufacture, and sell cutting-edge 3D portable and automated measurement technologies that provide innovative solutions for applications such as 3D scanning, reverse engineering, quality control, non-destructive testing, product development, and numerical simulation (FEA/CFD). Its products and engineering services redefine the boundaries in a variety of industries, including automotive, aerospace, consumer products, heavy industries, manufacturing, oil and gas, power generation, research and education. With headquarters and manufacturing operations in Lévis, Québec, Creaform is present in more than 85 countries, through its 14 local offices located all around the world and a network of over 125 distributors. Creaform is a business unit of AMETEK Inc., a leading global provider of industrial technology solutions serving a diverse set of attractive niche markets with annual sales over $6.0 billion. www.creaform3d.com