Lidar News recently had the opportunity to interview Bret Bienkowski, LSIT at Tetra Tech. Bret is their Mobile Mapping Survey Manager. He provided his valuable insights on their use of 3D laser scanning and mobile lidar.

Can you please provide a brief overview of your professional background and experience with 3D laser scanning/lidar technology, as well as a brief history of the growth of your group and its use of 3D technology? Please include an idea of the timelines.

In 2008, I graduated from the University of Florida with a degree in geomatics and a focus on laser scanning. Since then, I have worked for numerous engineering firms doing terrestrial and mobile lidar, collection processing and registration. In addition to working at engineering firms, I was the Terrestrial LiDAR Segment Manager at RIEGL USA for 4 years. My time at RIEGL gave me the privilege to work with many different lidar users and understand a wide variety of use cases.

I have since worked for Tetra Tech for the past two years in our Geomatics division. My focus has been to educate and bring more lidar technologies to the group. Before I started with Tetra Tech, my interest was mainly focused on aerial lidar and photogrammetry projects. I was specifically hired on to grow the mobile mapping practice in the US. Since I joined the firm, we have added a static scanner and a new custom mobile/UAS system.

Can you provide an inventory of some of the primary 3D surveying and mapping hardware and software that you currently use, as well as any other related products? Please include an idea of the timeline of purchases.

In 2019, we purchased the RIEGL VZ-400i terrestrial laser scanner for our work in the oil and gas industry. This year, we custom designed a dual head, multi-platform mobile LiDAR system that uses the RIEGL VUX-1HA kinematic LiDAR sensor and the Applanix AP60 IMU package.

With our RIEGL systems, we are running both RiSCAN PRO and RiPROCESS for data registration. Last year, we also increased our UAS fleet to include a DJI Inspire 2. For this system, we are running PIX4D for image registration and point cloud generation.

What attracted you to the use of RIEGL hardware and software? Did you look at other products? Why did you choose RIEGL?

We chose to go with RIEGL due to the high precision of the equipment, in combination with the robustness of their software, and its ability to register data easily and efficiently. We have used multiple competitors’ systems, but we have found that RIEGL’s software is the most user friendly and reliable. We see RIEGL as a major upgrade.

How do you integrate RIEGL products into your workflows? What were some of the challenges with that? What were some of the best practices and lessons learned?

We have transitioned into the RIEGL software easily as it had many similarities with existing software suites. Our workflow has been centered around lidar and processing data to extract survey grade deliverables. The use of the RIEGL systems and software suites facilitate this well and give us the reporting that allows us to not only have confidence in the results, but also gives us the information needed to include in our survey reports.

The use of our new VUX Rapid system allows us to keep up with the dynamic nature within our industry and allows us to quickly respond to requests as well as the ability to travel with the equipment anywhere in the world.

Can you provide a brief overview of two or three of the projects where you made use of RIEGL’s technology? Can you provide any thoughts on time savings vs. other methods? Any thoughts on return on investment?

We did a project in Seattle for the Navy where we had to combine hydrographic surveying and above water line lidar surveying to create a total site picture of the pier. For this project, our new rapid mobile system was ideal because of its easy portability and mounting onto our hydrographic survey vessel. The use of LiDAR was essential as we needed to merge the below water multibeam sonar data with the mobile LiDAR collection. The only way to ensure an accurate adjustment was to have the high point density of our dual head system to ensure that we were getting dense coverage in the short window of low tide where the two data sets could overlap.

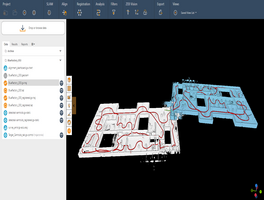

Another great project that we recently completed was for a new turnpike that is being constructed in Oklahoma. For this collect, we used the VUX Rapid to be able to quickly collect as-built conditions and identify any out-of-spec items that could be corrected before final project competition. By using 3D lidar, we were able to quickly register the data set and compare that to the designed surface model and identify areas of deviation. With this method we were able to quickly isolate three sites that did not meet the design and have them corrected before they became a problem with the next phases.

What do you see in the future for the use of 3D technology on your projects? Are you investigating other advanced technologies that will open up new business opportunities?

The future of the use of 3D is quite bright for us. We have been working to integrate the new technologies into our workflows as well as educating our engineering teams on the added benefits that can be achieved by using them. Speed and safety are not the only two added uses and by showing our teams what can be possible, it allows them to take it even further and use those added features to improve designs as well as reduce overall costs on projects. As we look to the future, we also look to the advances in the technology and how new systems will be smaller, lighter and more accurate. All of this will help to drive the technology and the use of the equipment even further.

Note – If you liked this post click here to stay informed of all of the 3D laser scanning, geomatics, UAS, autonomous vehicle, Lidar News and more. If you have an informative 3D video that you would like us to promote, please forward to editor@lidarnews.com and if you would like to join the Younger Geospatial Professional movement click here.