Throughout this event, Creaform will demonstrate practical applications of its 3D scanning technologies to improve quality control and quality assurance in sheet metal manufacturing.

Creaform, a business of AMETEK, and a worldwide provider of automated and portable 3D measurement solutions, announces its participation in EuroBLECH 2024. Creaform will showcase its most recent solutions designed specifically for quality control (QC) and quality assurance (QA) applications in the sheet metal industry. Experts will be available to demonstrate how Creaform”s technologies can optimize quality control processes, reduce production costs, and ensure the highest quality of parts.

Choosing the right measuring device for stamped or laser-cut sheet metal parts depends on specific needs. Some devices offer quick measurements, while others provide detailed and precise data. Some are designed for large parts, while others excel in measuring intricate details. In addition, there are portable and stationary tools as well as those using probing or scanning technology. Selecting the appropriate device ensures high standards of quality and efficiency, particularly in the sheet metal industry.

Portable Laser-based 3D Scanners

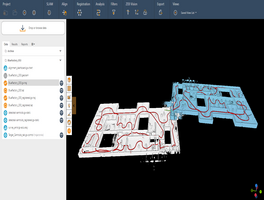

Geo-positioned, portable laser-based scanners, such as Creaform’s MetraSCAN BLACK|Elite , are unaffected by ambient lighting, surface reflectivity, or the number of images taken. It relies on the amount of raw data captured, ensuring high accuracy. The technology allows easy deployment without positioning targets and compensates for vibrations and environmental instabilities. As a portable device, it enables on-site measurements directly on the shop floor, making it ideal for quality control and troubleshooting in production environments.

The HandySCAN 3D|BLACK Series is another portable, high-accuracy handheld 3D scanner suitable for quick, on-site quality assessments and reverse engineering. It captures fine details and large volumes thanks to its high-performance optics and multiple blue-laser technology. With ultra-fast measurement speeds and instant meshes, users can cut down the time it takes to generate workable files, accelerating workflows in time-pressed projects.

Read More:

3D Modelling

Laser Scanning

Manufacturing

Subscribe to our newsletter

Stay updated on the latest technology, innovation product arrivals and exciting offers to your inbox.