Winter Garden, Florida – A Center for Excellence and Expertise in Survey Techniques and Technology

We are pleased to have the opportunity to be featured in Lidar News. We are RIEGL customers, as we own the VZ600i, and RIEGL is a survey customer of ours. We perform bi-annual surveys of the RIEGL Calibration site in Florida to ensure the absolute accuracy of the aerial targets for the RIEGL sensors to be calibrated against for their new and existing customers. The scope of our survey work is detailed here:

We surveyed RIEGL’s calibration field consisting of 46 reflective foil targets. These include targets mounted on top of concrete columns at distances from our collection stand ranging from 10m to 135m, as well as three plates with a target in each corner at 100m and a panel at 556m with targets in each corner. The survey was completed using a 0.5sec total station that was calibrated within the last 12 months each target was collected with a range accuracy better than 3mm and an angle accuracy better than 3’’.

We would love for Lidar News to consider this story from the perspective of a 36-year-old traditional survey firm that has adopted LIDAR into our traditional workflows to propel our company forward and based on our successful performance in survey and proximity to RIEGL’s USA HQ, they selected Allen and Company to perform calibration surveys for their calibration site.

- Can you please provide a brief overview of your professional background (s) and experience, particularly with 3D laser scanning/lidar technology, and/or a brief history of the growth of the company and its use of 3D technology? Please include an idea of the timelines.

Allen and Company are a 36-year-old survey firm located in Wintergarden, FL. Over the last 5 years we have started to integrate LiDAR into our workflows to allow us to provide a wider array and higher quality of services to clients. We leverage terrestrial LiDAR using the VZ600i, unmanned systems with XT32 and mobile SLAM with VLX. We are road mapping an upgrade to the RIEGL Vux-120 or comparable RIEGL system in the next calendar year.

- Can you provide an inventory of some of the primary 3D surveying and mapping hardware and software that your company currently uses, as well as any other related products? Please include an idea of the timeline of major purchases.

–RIEGL VZ-600i

-Hesai Pandar XT-32

-NavVis VLX

-Leica RTC 360

Traditional Survey Equipment and GPR

Civil 3D, Bentley Open-Roads, MAGNET field, Topcon data collectors, Topcon GPS, Sokkia data collectors as well as Leica and Sokkia digital levels.

Screening Eagle GPR units with GPS, ViDoc RTK, Vermeer Vacuum Excavation Trucks

- What attracted you to the use of RIEGL hardware and software? Did you look at other products? Why did you choose RIEGL lidar sensors?

We were attracted to RIEGL hardware and software by the reputation that they have for accuracy and precision in a wide range of versatile form factors. Allowing us to use them in different applications to provide timely and accurate surveys to our clients while reducing the amount of internal training needed since they are in the same ecosystem. We have evaluated several sensors even conducting an unbiased evaluation of them on a local site in Florida and publishing the results and we found after that study that the RIEGL VZ-600i met and exceeded our needs and expectations and now we are looking at adding a UAS based LiDAR Drone to the company’s toolbox.

- How do you integrate such a wide range of RIEGL products into your workflows? What were some of the challenges with that? What were some of the best practices and lessons learned?

For us integrating the RIEGL products into our workflows was very smooth. For some it’s learning a new piece of software and hardware that is intuitive but that is very easy with training. The biggest challenge for us is integrating all LiDAR data into our traditional surveying workflows. It is a balance of finding out which portions of a project we want to use LiDAR for vs traditional survey or even photogrammetry to create the most seamless and timely final product that addresses what the client needs. It’s an enjoyable challenge though that is only present due to technology driven progress in the industry.

- Can you provide a brief overview of two or three of the projects where you made use of RIEGL’s technology? Can you provide any thoughts on time savings vs. other methods? Any thoughts on return on investment?

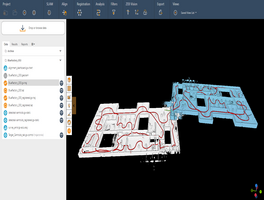

Our favorite project that we recently did using RIEGL sensors was the 2024 Lunabotics competition we did with UCF’s Exolith Lab and NASA. We used the RIEGL VZ-600i scanners to scan and produce volumetric calculations in near real time to judge the amount of lunar regolith, a moon dirt simulant, moved by remote and autonomously operated robots. It was a great competition and the onboard real time processing of the RIEGL sensor really stood out! It was the only sensor that was rugged enough for the simulated lunar conditions. We put the IP65 rating to the test!

- What do you see in the future for the use of 3D technology on your projects? Are you investigating other advanced technologies that will create new business opportunities?

As time progresses on, we would like to increase the percentage of the project that is done with scanning for traditional surveys and incorporate it into as many of our service offerings as possible while still offering customers the highest level of accuracy to exceed their needs. We are also proving out workflows combining, traditional survey data, with terrestrial, UAS and subsurface data, including GPR and utility daylighting from vacuum excavation to create comprehensive data sets for digital twin and single source of truth applications for developers, constructors and end-user applications. The data that these systems produce can be tremendous so we are exploring ways to leverage AI in our workflow to make sense of disparate data sets leveraging computer vision and machine learning to identify features and anomalies that may have otherwise gone unnoticed. There is no expiration on great data capture and the data can be reused numerous times as new use cases arise.

For more information on Allen and Company CLICK HERE.

For more information on RIEGL CLICK HERE.

Note – If you liked this post click here to stay informed of all of the 3D laser scanning, geomatics, UAS, autonomous vehicle, Lidar News and more. If you have an informative 3D video that you would like us to promote, please forward to editor@lidarnews.com and if you would like to join the Younger Geospatial Professional movement click here.