Lidar News had the opportunity to interview Georg Schroth, Co – Founder and NavVis CTO concerning the recently released NavVis VLX wearable mapping system.

1. Please provide a brief bio and overview of your history with NavVis.

My name is Georg Schroth, and I’m the Co-founder and Chief Technology Officer here at NavVis. We established the company in 2013 to bridge the gap between outdoor and indoor digital mapping. As a spin-off from the Technical University of Munich (TUM), our indoor positioning and mapping technology is the result of years of academic research.

It all started when I visited the Stanford University GPS Lab in 2007, where I came up with the initial concept to develop a fundamentally new approach to indoor positioning based on computer vision. This topic became the basis of my Ph.D. research at TUM.

Today, NavVis hardware and software is a platform to create and operate a digital twin of the built environment. We employ 200 people around the world, with headquarters in Munich and offices in New York and Shanghai. Our products and services are used by some of the leading companies in the automotive, construction, real estate, and insurance industries.

2. Can you provide any insights on the early days of the development of NavVis VLX? What were the driving forces for developing this type of product and for the final design?

The first concrete steps towards NavVis VLX were taken back in 2017, when the very first prototype was built. We looked at various potential alternatives of the overall system design, ranging from a big backpack to a small handheld scanner. All these approaches have their pros and cons when it comes to versatility, robustness, and – most importantly – data quality. Ultimately, we realized that the optimal design could be the best of all worlds: NavVis VLX is unique because it allows for actively mapping even the smallest niches like a handheld device while also carrying the sensors needed to provide the best data quality.

But perhaps the most important design criteria for us was to allow for full 360-degree panoramic images that can be taken on-the-go in fractions of a second. For many applications and use cases around the digital twin of a building, an immersive and intuitive 3D panorama in high definition is essential. We know from our network of laser scanning professionals that for many of their clients, this is the primary way they explore their mapped buildings (aside from 2D floor plans). Making this possible while simultaneously concealing the person doing the mapping has been a major challenge, and the feedback from our partners was extremely helpful.

3. Approximately what percent of the hardware and software technology of NavVis M6 was used to create NavVis VLX? Can you provide some details on the use of SLAM in NavVis VLX?

Simultaneous localization and mapping (SLAM) technology is one of the building blocks for our hardware. Our devices can reliably track their position with extreme precision – in all 6 degrees of freedom – for extended periods of time, even when objects might be in motion around it. In this regard, we started down the development path of VLX before we even founded the company back in 2013.

Achieving the degree of accuracy required by surveyors is a challenge that no one in the mobile mapping industry was able to solve until NavVis M6 was released in April 2018. We made a huge breakthrough with a design based on four laser scanners and a few standard assumptions, e.g., that the device is not turned upside down.

With NavVis VLX, our Design & Engineering Team went even further: every motion must now be accounted for (including upside down) and we limited ourselves to a set of two multi-beam laser scanners to miniaturize the system. So yes, our work on SLAM continues with NavVis VLX, and is part of a process stretching back more than seven years.

Besides the trajectory of the device, quite a few more key components had to be developed to achieve this level of point cloud quality. For example, the point cloud fusion step allows for treating every single range measurement differently, depending on the properties like the angle of approach, the strength of the signal received, and many more.

Fusing range measurements taken at different locations and points in time allows us to get to a much higher accuracy than the specs of the raw laser scanners. Also important is that this fusion step allows us to remove artifacts like people moving through the scans.

4. Who are the primary target markets for the VLX? Can you provide a high-level discussion of competitors, pricing and expected ROI?

With NavVis VLX, we’re targeting laser scanning professionals in the surveying and mapping service industry or within the architecture, engineering and construction industries. For those markets we provide a device that’s very versatile and suitable for most building documentation projects as the primary scanning device.

The pricing is comparable to what you’d pay for high-quality terrestrial laser scanners, but with the added advantage of being up to 10x faster during data acquisition. The accuracy of the device is suitable for typical as-built documentation needs, such as LOD 300 BIMs or floor plans with a scale of up to 1:50.

Compared to other mobile devices in the market, we offer best-in-class point cloud accuracy and quality with very low noise levels, homogeneous point cloud structure, and very realistic coloring. Furthermore, we provide a reliable and scalable workflow to register point clouds using control points (surveying targets).

Finally, there’s NavVis IndoorViewer, a dedicated application which enables draftsmen, BIM modelers, project managers and end-users to intuitively interact with their scanned building through any standard web browser.

5. Can you provide more detail on the recommended procedures and best practices for achieving survey grade accuracy, particularly for multi-floor projects? Can you provide any test results with detailed least squares, or similar analysis? Perhaps the measured RMSE errors and confidence intervals.

A typical project might be for instance 1,000 sqm of office space. This can be scanned with NavVis VLX in one hour and within one dataset. This can include narrow spaces like Mechanical, Electrical and Plumbing (MEP) rooms and multi-floor spaces with staircases. In more open environments, even 3,000 sqm can be captured within an hour.

All of this assumes that a dense set of high-quality panoramic images are taken to provide an in-depth documentation of the building, which is one of the benefits of a mobile mapping system. If you really need to speed-up mapping even further, you don’t need to take panoramas at all and can generate only an intensity colored point cloud.

For larger mappings that involve multiple datasets that need to be registered against each other and a given coordinate system, it’s beneficial to use at least three control points (surveying targets) per dataset for registration. In addition, NavVis processing software can algorithimically optimize the global geometry of the point cloud based on control points. This is especially useful when the project doesn’t allow for “loop closures”, e.g., in very long, narrow corridors.

In one test project, a garage of approximately 1,500 sqm was scanned in 30 minutes. Without using control points for point cloud optimization, an absolute accuracy of 8mm has been achieved at 68% confidence, and 18mm at 95% confidence. Further details about this test project will be shared soon in a dedicated white paper.

6. Although it is more flexible than a cart, there are still going to be really tight places where it might require a handheld device. Do you have a recommended workflow for that kind of data fusion?

We recognize that no single tool is best suited to meet all requirements. Since most of our customers already own a terrestrial laser scanner from Faro, Leica, or Trimble, we recommend that they fill in such super tight areas with those devices. You could also use a handheld scanner, but only if the quality is sufficient for your application. Our NavVis IndoorViewer software can support all kinds of E57 scan data, so it’s easy to import multiple point cloud datasets from more than one scanning device and manage them in one place.

7. Can you describe the post processing of data, along with the QA/QC such that the reader has a good understanding of how to go from raw data to georeferenced point cloud with a specified accuracy at 95% confidence level?

Achieving the specified accuracy relies first and foremost on collecting good data. While mobile mapping is comparably easy to do but still new to most of our customers, we offer training and certification sessions to ensure best quality. These cover techniques such as walking speed and creating loop closures, which occur when you visit the same place twice in one dataset. By doing this you give the post-processing algorithms high quality data to work with to build an accurate map.

As mentioned above, to get a referenced point cloud you can use control points. Together with our customers we developed best practices to minimize the time required to survey control points and to place them at the optimal spots. The workflow allows to survey the control points after the mobile mapping to provide additional flexibility. While control points are surveyed in a metric local coordinate system, a reference to the world coordinate system in WGS84 can be provided to georeference the mapping.

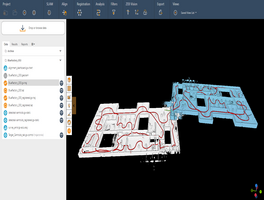

To ensure proper quality we have introduced a few options that help speed up this process and to make sure no details are missed. One of them is our so-called quality map that very easily indicates which areas have been mapped and in what density. It also shows the trajectory with time stamps, as well as the location of the panoramic images. When using control points, they can also be used to verify the accuracy of the scan as the deviations are automatically computed.

Last but not least, NavVis IndoorViewer provides a comprehensive set of tools and options to investigate the quality of a set of scans in detail, like section views that are rendered in real-time.

8. Can you discuss data formats and the issue of data interoperability? Are you supporting E57?

The typical output of the VLX is a registered colored / intensity point cloud and high definition panoramic images, and we use open industry standard data formats like E57 wherever possible. This is just one of the available data outputs from NavVis VLX, together with LAS, PLY, PTS, and XYZ.

The data captured by NavVis VLX can be applied to a wide range of applications. This includes standard building documentation such as CAD drawings and BIM, and innovative digital twin solutions like NavVis IndoorViewer.

In addition to the existing integration with Autodesk Revit, NavVis has also launched collaborations with PointCab, ClearEdge3D and Hemminger for Bentley Microstation. This will help ensure that NavVis VLX seamlessly aligns with the existing workflows of third-party solutions.

9. Can you provide any insight on the NavVis VLX road map?

The response to NavVis VLX has been tremendous, with many positive reactions from both existing partners and potential customers. I’m very proud of what our team has achieved; it’s been something we’ve been building towards for some time now and our hard work has paid off.

Much like in the past, we’ll continue to ship major new innovations as part of our software updates. So, expect that a NavVis VLX you buy today will fully benefit from further advances in data processing and quality. Beyond data quality, we’re working on workflow topics, like a cloud-based processing option that’ll save you hours of time while keeping your data fully in your hands. The collaboration with market leading companies like Autodesk, ClearEdge3D and PointCab can help our customers noticeably, and we plan to push this further as well.

Finally, there will be quite a few new additions to NavVis IndoorViewer this year that allow our customers to level up the offerings for their end-customer to services that go beyond conventional scanning output. As an example, the new measurement tool will get a major sharing and annotation functionality that enables the use of the scans for project management at the client’s company.

####

On 4 June at 16:00 CEST we’ll be live streaming a hands-on demo of NavVis VLX from our HQ in Munich. Your readers are welcome to attend and can put questions to me and one of the D&E team leads. Attendees will also receive the data from our live mapping after the webinar so they can judge for themselves what NavVis VLX is capable of. Join us! https://www.navvis.com/vlx-live-webinar

Note – If you liked this post click here to stay informed of all of the 3D laser scanning, geomatics, UAS, autonomous vehicle, Lidar News and more. If you have an informative 3D video that you would like us to promote, please forward to editor@lidarnews.com and if you would like to join the Younger Geospatial Professional movement click here.