3D Laser Scanning To Expedite The Installation Of ACM Panels

Client Testimonial: Contracting TruePoint to do a 3D laser scan has been one of the best project decisions we made. The entire process was quick and accurate. TruePoint was incredibly accommodating to our needs. They were able to turn a complex design into a field friendly document. With their help we were able to reduce cost, increase productivity, and deliver the project on time. Working with TruePoint has changed the way we field measure, layout and install projects. — Vincent M, Superintendent

Project Manager Insight: “We have worked on a number of projects with this client. This project was the real breakthrough moment for this client to understand the value of laser scanning,” Nate Baker, Northeast Regional Manager.

Location: Queens, New York

Task: Our client specializes in installing exterior envelope systems for commercial and industrial buildings. On this project, they were installing ACM (Aluminum Composite Material) panels to the canopy of a newly constructed airport terminal. According to Nate Baker, Northeast Regional Manager for TruePoint, “The construction plans did not match the existing conditions at the site. A deviation could cause a major issue. The installation process needed to be precisely planned to avoid rework.” TruePoint 3D laser scanned the canopy and curtain wall façade to capture true as built data and generate a 3D model and 2D drawings to facilitate the installation.

Challenge: The shape of the canopy was complicated and stood 65 feet in the air. The client needed field verification and a plan to expedite proper installation of the panels. “They are working overhead in a lift, there was no room for trial and error. Our client was not interested in hanging panels, discovering issues and having to take them back down,” Baker added.

Solution: TruePoint conducted a site walk to devise a plan for the client. Laser scanning obtained true as-builts for the client and took away any guesswork from this project. To circumvent the active construction site, the project manager scanned the site at night to eliminate movement and trades working.

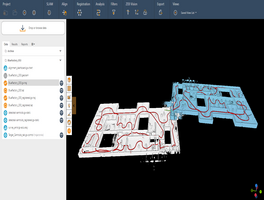

Deliverables: TruePoint developed practical technical deliverables for the client. An as-built Revit 3D model of the canopy was developed from the point cloud data captured. From the 3D model, TruePoint created 22″ x 34″ 2D drawings with the panel layout the client could take to the field. The panels were labeled with a custom number and included cut and shim points. TruePoint delivered a point cloud file, (.rcs file format), JetStream Viewer files (.lgs file format), 3D Modeling (.dwg file format) and 2D Drawings (.dwg file format).

Added Value: ACM is the most commonly used envelope of buildings and functions as the structures’ primary weather barrier. Accurate panel measurement is crucial for installation. Panels are installed in a directional fixed order on a mounting system using shims for leveling and clips for attaching them. A strip hides the gaps between panels. If they are not installed correctly, they can leak. The installation process needs to be as precise as possible, if not installed and sealed correctly, they can leak water. By working hand-in-hand with the client, TruePoint was able to provide the exact measurements needed in order to properly install the panels.

TruePoint provides engineering solutions to help clients improve productivity and expedite field work. For 3D laser scanning services in New York, call 646-430-2444 or email newyork@truepointscanning.com.

Note – If you liked this post click here to stay informed of all of the 3D laser scanning, geomatics, UAS, autonomous vehicle, Lidar News and more. If you have an informative 3D video that you would like us to promote, please forward to editor@lidarnews.com and if you would like to join the Younger Geospatial Professional movement click here.